FOCUSED RESOURCES SERVICES

Search

Focused Resources is a WBE, SBE, DBE

Operations

Focused Resources shores up their clients with custom-made practices to integrate health, environment and safety regulations into their daily operations.

Reliability Engineering/Root Cause Analysis/Leak Prevention - Retail Gasoline Outlets - Compliance Program Manager - Ms. Coughlin led the national team for a major oil company's nine regions involving thousands of service stations/retail gasoline outlets. This hand-selected Dream Team developed nationwide procedures and programs (now used across the oil industry as standards of operation). The comprehensive program includes equipment (design, installation, operation, monitoring, maintenance, removal), media (product, water, waste, air) management, monitoring & reporting, leak detection, training, owner/operation agreements, permits, regulations and legislation. Due to Ms. Coughlin's expertise she has also been a member of numerous local, state and federal task forces and industry committees who developed the Certified Operator Training protocols, leak detection equipment design standards, enhanced/site-specific HAZCOM elements, and creative California Underground Storage Tank (UST) fund cost recovery criteria (when the CA UST Fund threatened to go bankrupt).

Ms. Coughlin, and her team, are renown for challenging the historic, narrowly-focused approaches to Leak/Spill prevention and Retail Outlet operations. They introduced the 'Human Factor' (90%) versus 'Equipment Factor' (10%) approach to the root-cause analyses of leaks/spills and applied Reliability Engineering to the decision processes involving equipment choices at service stations. These practical Leak Prevention programs have never been more important, now that most service stations, nation-wide, are operated by independent operators/marketers.

Industry Standard - Data/Information management/preservation - Major Oil Companies- Ms. Coughlin has served on, and led, formal and informal teams that designed procedures/systems to improve data-management processes for hard copy and electronic records. Under the agencies' and legal courts' pressure of conducting "good and thorough searches under the pains and penalty of perjury" many businesses can not comply. Our processes focus on the ability for the business units to use these previously stockpiled records as valuable assets. We find we can also eliminate unnecessary data. Our projects have shown a monumental return on investment used by our clients to reinforce why data management makes good business sense. Ms. Coughlin was an original conceptual designer, and an ongoing process enhancement provider, for this industry standard. With these systems (active & archived record databases) thousands of users have been able to defend their company's legacy operations in claims/litigation, due diligence, mergers & acquisitions, operational efficiencies, and cost recovery/allocation.

Update: Ms. Coughlin's original (1980s) format for coding & indexing (bibliographically) project and/or facilities records, continues to be an industry standard. Ms. Coughlin has also proven that the 'evergreen' record indexing may also require a comprehensive document review, by a subject-matter expert, to enhance document & folder descriptions (contained within a record database). Our team has assisted our clients in addressing thousands of claims against them more efficiently and successfully. This practice continues to be a successful standard in the industry for both hard-copy as well as electronic data in active and archives storage.

Compliance Reviews/Audits/Inspections - Confidential clients - We are contracted as technical support (including data management) associated with due diligence for real estate activities. These activities include real property transfers (sales or acquisitions), and audits of operations and tenants for compliance with applicable regulations, equipment manufacturer's warranties, insurance policy language and/or contractual agreements. Due to our wide-range of expertise, our extensive roster of talent, and the technology (Skype, WiFi, bar-coding, hand-held computers) tools available, threats are found quickly and remedied effectively without interruptions to business/production flows.

Large-scale Data

Management projects - Consulting Expert - Beginning in the early 1990s Focused Resources' team members have

managed large-scale data management projects. Through the evolution of hard-copy to electronic data, as well as database

and software development, our expertise has expanded with the products

development. Early on we

have been intimately involved with this evolution from Sun WorkStations

(graphics programs beta-tested on the 100+ year old former Tosco Avon refinery), through the development of software

using 3D models. One evolution (initially SiteManager & DataManager) involves the development of Consolves, Inc.'s

PLUME. From Consolve, Inc.'s website: "PLUME cuts by 50-80% the number of soil and water samples needed to identify the area of earth contaminated by a hazardous material spill."

We have also managed millions of documents, making them easily retrievable by converting them into electronic formats, reviewing and capturing the content in searchable databases. These efficiencies have reduced expenses associated with: (1) having to recreate the data, (2) penalties for not having the data, (3) making well-informed decision, based on the data, or (4) not being held hostage by third-parties that have a better understanding of the data. By comprehensively managing data, our clients have been able to seamlessly transfer projects between project managers and subcontractors, without the loss of institutional knowledge.

RCRA/UST compliance program for 20 terminals in the Pacific West Region (California, Oregon and Washington) as well as the major program elements for a nation-wide program - Shell Oil Products US - Program includes:

- Underground Storage Tank (UST) Compliance Guide for Headquarters Environmental support staff (modified for specific geographic areas);

- Thirteen States - Regulation comparisons with the Federal regulation and specific implications to operations;

- UST Determination Chart (addresses traditional and non-traditional underground structures);

- Facility UST Compliance Plan - Specific for each of 20 terminals(included all requirements (equipment, all historic paperwork, maintenance, certifications, operations manual for leak detection); and

- Conducted 20 Training Classes for Headquarters staff, Terminal Management and Operators.

Functional Illiteracy Component for Incident Reduction/Safety Programs - We began as a small team of conceptual designers, within an oil company Headquarters (HQs) group, creating Incident Reduction program elements. Early on in our research (audits and inspections of operations), originally due to the incidents/accidents, it became apparent that a large percentage (estimated 60%) of manual tradesmen/operators were "functionally illiterate" with respect to reading and writing English. Simply put they could not read signs, maps, plans, equipment manuals, training materials, etc. within the operations and corporate safety called it "the dirty little secret". Once discovered this small group of HQs staff formed a cross-functional team to have process-savvy behavioral scientists meet with refinery/terminal/pipeline personnel and safety experts to create a beta-test version of a safety program not wholly reliant on written materials. The results of these specialized reviews of the operations led to the industry standard known as Behavior Based Safety/Loss Prevention System.

Due to wide-range success, we continue to use this process thinking to break down complicated issues into manageable, relatable 'pieces'. Our regulatory compliance expertise, paired with this process thinking, is best used for root-cause evaluations, creation of practical health, environmental and safety programs, development & implementation of training programs, and tenant audits. We also find, due to our broad operational experience, we are excellent Consulting Experts, expert witnesses, and creators of Jury Exhibits for litigation support.

A proven leader in facilitating industry improvements in Safety:

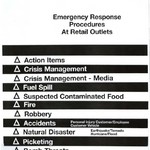

Contractor Safety - Retail Gasoline Outlets - we were instrumental in development and implementation of a Contractor Safety program which included administrative elements(licenses, insurance, training logs, budget, schedule, work orders, monitoring forms) and project-execution elements (tail gate meetings, inspections, personal protective equipment, training). This program remains the standard in the oil industry which is extremely important with more independent marketers.

Safety Services - Nation-wide Standard, Contractor Safety Program - we collaborated with leading safety/refinery "turnaround" specialists [(TIMEC) now Transfield Services] to combine industry-wide programs into a comprehensive Refinery-Specific, Contractor Safety program presented at the National Petroleum Refiners Association's Annual meeting.

Revised Process Safety Management Program (PSM) - Bakersfield Refinery - under the direction of the Plant Management, we led the team of safety and operational specialists to use Reliability Engineering methods to combine several units/departments' equipment specifications, operational manuals and safety procedures into one plant-wide Process Safety Management Manual/Program.

Environmental Assessment for school/classroom expansions - Confidential client: School District - California - We were hired as the Lead Environmental Investigator/Evaluator to conduct research and evaluation on three large high schools in a major Unified School District. During inspections we found the presence of friable asbestos (reportedly asbestos abatement had been completed), a large subsurface cistern (circa 1910) in the basement of a building (never properly maintained or covered), improper handling and storage of chemicals and waste, improper training of on-site and district maintenance personnel, improper operation and maintenance of transformers, underground tanks, underground sumps, etc.

National Enforcement Investigation Center (NEIC) Audit by USEPA and Department of Justice - Client: Major oil company - We were originally, hand selected by the management of a Bakersfield Refinery to develop and implement a data-management program during a multi-agency "Enforcement" audit. Within 4 days of receiving a 10-page, single-spaced list of data categories, investigators of the United States Environmental Protection Agency and the United States Department of Justice arrived on site to investigate the facility. This one-week investigation involved the facility's entire operation, staff and management and their compliance with a myriad of regulations covering multiple media (air, water, waste, chemicals). We designed and implemented a unique, 'triage-style' Information Management (IM) process flow. The process flow required a series of Quality Control measures (every page reviewed by legal counsel), allowed for the data (compiled in a specially created secure file/data room) to be available for review by federal enforcement agents. The IM process flow allowed the facility to keep control, and preservation, of the data, for the on-going operations of the refinery. Reportedly our protocols became the federal National Enforcement Investigation Center (NEIC) audit/information management standard.

Following this National Enforcement Investigation Center (NEIC) Audit, we led an extensive evaluation of the deficiencies in the refinery-wide information management & information preservation (IM/IP) system, for both active and archived records, for the development of an enhanced program. This enhanced program also complied with the major oil company's Retention Schedule, most likely, for the first time in its history of operation.